Industrial Cleaning & Vessel Washing Equipment That Save Time, Labor And Cost

Vessel washing solutions are needed to maintain equipment to industrial specifics and to ensure product safety and integrity.

For companies that use any type of container in their mixing, production, or transport processes, reliable and efficient cleaning of these vessels can be a considerable challenge.

Thorough washing of containers is imperative. For food and beverage producers, pharmaceutical and cosmetic manufacturers, and other companies, their drums, vats, IBC containers, and other mixing vessels must be kept food and/or cosmetic-grade safe. Manufacturers of paint, pigments, dyes, inks, and similar products must also keep their containers free of residues that may compromise the integrity of their products.

Without in-house vessel washing capabilities, these manufacturers will frequently rely on a dedicated service provider to collect and clean or dispose of used containers. Depending on the size and cost of the containers, these service providers may collect them, clean them at an offsite facility, and return them for reuse. In other cases, vessels are cleaned manually with various cleansers and hand-operated tools, including power washers and other pressurized and/or heated flushing methods.

Such hands-on processes pose some hazards. It is often necessary to use caustic detergents or chemical solvents, as well as liquids that are heated to very high temperatures. Manual cleaning may also require a lot of downtime for equipment, special safety precautions, and a great deal of labor. The quality and consistency of the cleaning job can vary due to many factors.

Vessel washing with a dedicated, in-house unit makes this process safer, more consistent, far less labor and time-intensive, and more thorough. Automating the vessel cleaning process eliminates atmospheric and contact concerns, along with many other issues.

For companies that are seeking a better, more efficient way to clean containers, while reducing cost, time, and labor expenditure, in-house vessel washing is a reliable solution.

The Benefits Of In-House Vessel Washing

Vessel washing capabilities simplify and improve the container cleaning process. Equipment options include many different units that satisfy a range of facility and production requirements.

Vessel washing, as an alternative to outsourced cleaning or singe-use and disposal, provides many benefits for saving cost and reducing waste. Container inventory can be entirely maintained in-house. Fewer resources are spent on the collection of used containers for offsite disposal or cleaning, as well as the purchase of new ones.

With a properly implemented vessel washing setup, containers can be loaded on to a belt and atomically fed into the unit. They'll then come out clean on the other side, ready for reuse.

Alternatively, smaller units can include basic industrial cleaning equipment that allows operators to manually load the container for washing and simply remove it by hand once the process is complete. Even with more compact vessel washers, the cleaning process is highly efficient and isolated, making operations safer and faster.

NexGen Enviro Systems offers a complete range of industrial cleaning equipment that includes:

- Tank cleaning units that allow for a range of add on features and modifications to suit your specific needs.

- Drum washing machines that meet the requirements of manufacturers in many industries, including food and beverage processing and paint manufacturing.

- Container cleaning machines that work with containers of all sizes, shapes, and dimensions.

Vessel Washing Equipment Options

The vessel washing solutions provided by NexGen Enviro Systems will efficiently clean containers of all different sizes, including those as small as one to five-gallon buckets and canisters to large volume drums, vats, barrels, and IBC vessels that hold hundreds to thousands of gallons of liquid. Our state-of-the-art solutions work with metal and plastic containers that hold all manner of substances.

Vessel washers can work with water and detergent-based cleaning solutions and solvent or other chemical-based cleansers. These solutions are expelled under pressure and at set temperatures to thoroughly clean containers of all shapes, sizes, and volumes.

We provide vessel washing units that work interchangeably with both water-based detergents and cleaning solvents. For higher volume vessels, however, it is advisable to use a vessel washer that is exclusively solvent or water-based rather than a unit that works with both.

Vessel washing can be completed on the internal and external areas of the container or can be limited to the vessel's interior/cavity.

This is just the beginning of the individual options and capabilities that are available with the Basca vessel washers we offer.

Getting Started With A NexGen Enviro Vessel Washer

We are an experienced distributor of advanced industrial cleaning equipment and solvent recycling solutions. We're proud to be the only provider of Basca vessel washing solutions in North America.

We serve customers across many industries, predominately throughout the U.S. and Canada.

To get the best possible result from a vessel washing solution, tell us about the unique attributes of the production facility as well as the containers to be washed. Let us know the volume, shape, size, and former contents/contaminates of the vessels you use. We'll help you identify a solution that will best suit your company.

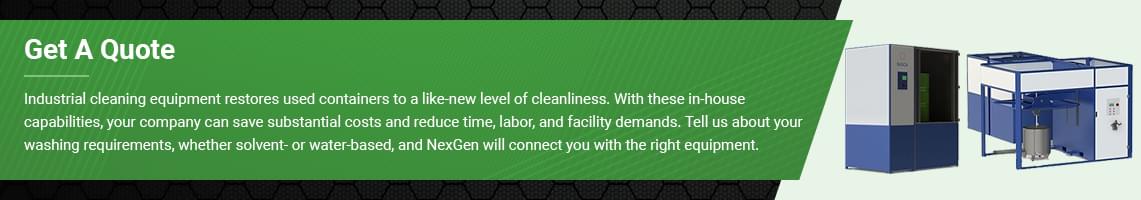

To tell us about your requirements and get a quote, contact us today.