Highly Efficient Solvent Recyclers

NexGen Enviro System's solvent recyclers provide a safe and efficient solution for recovering solvents and reducing waste during your production and manufacturing processes.

These high-performance systems recover fully usable, clean solvent from process waste streams. The result is a significant reduction in the time, cost, and space required to store and dispose of waste waster, contaminated solvents, and other hazardous materials. Our clients have lowered their operating costs, reduced their environmental impact, and improved their profit margins by recovering solvent that can be reliably reused during the production cycle, just like new.

Get More Information On Our

Small And Medium Volume Models

Solvent Recycling Equipment

Get More Information On Our

Large Volume And Continuous Models

Solvent Recovery Systems

How Our Solvent Recyclers Work

When solvent is required for the industrial cleanup process equipment or related parts, the resulting waste consists of a contaminated solution. This solution consists of the initial solvent, whether alcohol, acetone, or other cleaning liquid, and whatever substance was removed from the equipment, such as ink, paint, resin, grease, or oil.

Without solvent cleaning, the waste liquid must be stored until it can be properly disposed of as a hazardous material or until it can be transported to a dedicated recycling facility. Special procedures and capabilities are required for proper storage, transport, and disposal, which can be a costly part of the production process for many manufacturers. Every dollar spent on this process means fewer profits.

Having an on-site solvent recycler enables companies to reduce the costs and resources devoted to this aspect of their business. Recycling solvent in-house significantly reduces the amount of hazardous waste that requires special disposal. It also makes it easy to recover solvent for reuse, thereby reducing the amount of virgin solvent needed to be purchased.

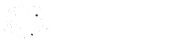

This is accomplished as dirty solvent enters the solvent recycler. Through a distillation process, the waste liquid is heated and vaporized, which separates the solvent from all contaminants. The vaporized solvent then passes through to a condenser. At this point in the process, the solvent vapor is cooled and returns to liquid form. The now-cleaned solvent is dispensed to a tank, drum, or other container to reenter the production or cleaning cycle.

The remaining waste contents that have been isolated from the recycled solvent can then be disposed of in a much simpler manner. By recovering viable solvent through the recycler, there is far less waste to be hauled offsite, less space to dedicate to waste storage, fewer steps needed to achieve regulatory compliance, and greater risk reduction.

The amount of solvent recovered through NexGen solvent recyclers is substantial. 99 percent of every gallon of potentially usable solvent that enters the recycling system can be recovered, regardless of the type of process.

Why Choose NexGen Enviro Systems As Your Solvent Recycler Provider?

NexGen Enviro Systems has been designing, developing and building solvent distillation and recovery solutions for nearly three decades. With over 8500 customers served across North America, we have extensive experience addressing the needs of manufacturers and service providers across numerous industries, including:

Virtually any producer of products or service provider that uses solvent at some point in their process can benefit from solvent recycling systems.

Our solvent recyclers have been designed to be the perfect combination of an off-the-shelf solution with many customizable features that can be tailored to your specific process.

Our equipment standards accommodate many different demands, and extra features can be readily adapted to a range of requirements. That means you get to essentially create a custom unit without the cost and time required to build equipment from the ground up.

Solvent recycler features can include automatic loading of waste solvent, automatic discharging of residual waste, continuous operation, vacuum assist for higher boiling solvent processing, automatic scraper blades to keep fluid in motion and aid in residual discharge, Teflon coated tanks, stainless steel condensers for highly acidic or caustic mixtures, and more. We can customize a solution to the needs of any customer.

All of our machines are UL 2208 and ATEX II 2G explosion-proof listed.

In addition to compliance with the highest safety standards in the industry, our equipment operates on a superior level of automation and allows for exceptional ease of use. That translates into substantial time and cost-saving benefits for our clients. Operation is extremely reliable and maintenance is easy, which means that you avoid downtime and reliance on additional technical labor or repairs.

We provide one-on-one guidance and careful attention to your requirements throughout the process. We're here to ensure all of your questions and concerns are addressed before you make a purchase.

Use the contact form here on our website to tell us about your needs or call us directly. An expert member of our team can provide you with details on how a NexGen Enviro Systems solvent recycler can significantly improve your capabilities and save you time and cost.