Industrial Ink And Paint Bucket Washers For More Efficient And Economical Washing Capabilities

When buckets or containers are needed for industrial painting and printing, they ordinarily require specialized disposal once they’ve been used. A new bucket or can must then be filled with paint or ink to complete the next job. This is typically the process for industrial painters, printers, and other service providers that work with potentially toxic liquids. The cost and labor required for this approach add up quickly.

One way to reduce these expenses and cut down on waste is by utilizing an industrial bucket washer. With this equipment, paint and ink buckets can be cleaned and used liked new.

Industrial bucket washers remove the residue left on and inside various containers. As these substances require special processes for removal and waste disposal, simply flushing out the containers isn’t quick or easy.

Industrial ink bucket washers and paint bucket washers, however, make cleaning simple and streamlined. Buckets and containers can be refilled and used multiple times. This means that fewer resources are required at the front end and waste is reduced throughout the painting and inking process.

Easy To Incorporate Industrial Bucket Washers

Industrial bucket washers will clean buckets, cans, and other containers internally and externally. This equipment is easy to incorporate and maintain in just about any industrial facility that uses paint, ink, and other materials.

NexGen Enviro Systems provides industrial bucket washers and parts washers that are ideal for washing ink containers, paint buckets, and similar receptacles ranging from 1 to 25 kg.

Our industrial bucket washers are made from AISI 304 stainless steel. By its very design, it’s easy to maintain and allows operators to avoid contact with harsh and hazardous substances throughout the cleaning process.

The operator activates a pneumatic pump through a timer, which recirculates washing solvent from the storage tank to special rotating injectors, which then rapidly and thoroughly clean the drum.

Contact us to get a quote on an industrial bucket washer or to speak to an expert member of our team to discuss your requirements.

Printing Press Parts Washers For Ink Trays, Vessels, And Other Flexo Printing Components

Industrial and professional printing requires the use of highly specialized inks and other materials. The residue left behind after each job must be thoroughly cleared from the printing press to ensure the clarity and quality of the next one. Often this must be done by hand, which is not only labor-intensive but less than ideal for maintaining the integrity of printing press parts and components.

Ink trays, tanks, doctor blades, vessels, etc. all require specialized cleaning. For companies that use rotogravure and flexo presses, an efficient parts washing solution can make a major difference in job output and quality, while also reducing labor demands, and preserving the integrity of your equipment.

Speed Up And Simplify The Printing Press Washing Process

Printing press parts washers are designed to make the parts cleaning process simpler, faster, and more thorough. These machines are equipped with a trolley that makes it easy to load dirty parts from different areas of the facility and then transport them to the parts washing unit.

The operator can then slide the parts in the grid and start the washing cycle. This minimizes the need to handle printing press parts and mitigates contact with ink residue, harsh cleaning solutions, and other chemicals. Printing press parts washers provide a gentle, comprehensive cleaning that is far more consistent than that achieved through manual washing.

Flexo printing press parts washers save time, reduce labor and maintenance requirements, and enable you to get to the next job faster, thereby improving your output.

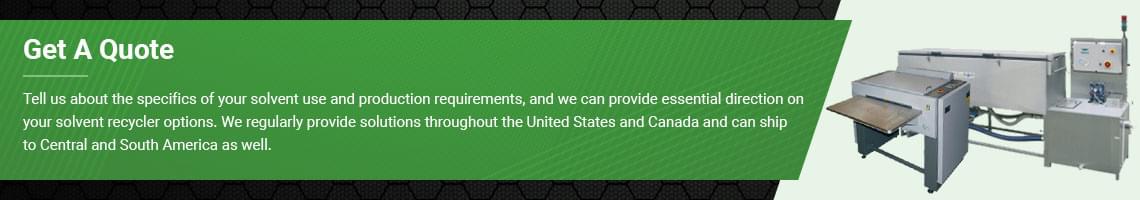

Get A Quote On A XTR WASH Printing Press Parts Washer

NexGen Enviro Systems can provide reliable solutions for companies that need flexo printing press part washers, ink tray parts washers, and vessels parts washers.

Our XTR WASH parts washer series includes units with PLC control panels that are set with various washing and rinsing programs. With these features, you can add a new level of automation to your production and maintenance capabilities.

The XTR M is equipped with oscillating solvent pipelines that feature mechanisms placed outside the washing compartment. This means that there are no moving parts present during the washing cycle. As a result, washer maintenance is significantly reduced.

This series includes units with various options for washing areas that accommodate operations and facilities ranging from small to large. Widths range from a minimum of 450 mm to a maximum of 1200 mm and can accommodate all standard equipment formats.

You can get a quote on a printing press parts washer or learn more about all available options by contacting us.